iVision Tech SpA

iVision Tech is a manufacturing excellence in the “Made in Italy” eyewear industry that guarantees high-quality standards from design to the realization of the finished product.

The company operates in its own 5,000 square meter facility in Martignacco (UD), which was acquired on October 1, 2020, through the acquisition of a business unit from Safilo Industrial S.r.l. The objective was to revitalize the industry and develop an independent eyewear hub in Friuli-Venezia Giulia.

The expertise of the operators, the performance of state-of-the-art 4.0 machinery, and the integrated production and quality monitoring dashboards translate into a production capacity of over 1.2 million glasses per year. iVision Tech embraces the philosophy of lean manufacturing, applying its principles of continuous improvement and aiming for two main goals: customer satisfaction and ethical business management.

Luxury brands, independent brands, and emerging brands recognize iVision Tech as an important strategic partner, synonymous with high product quality and service.

Divisione Eyewear

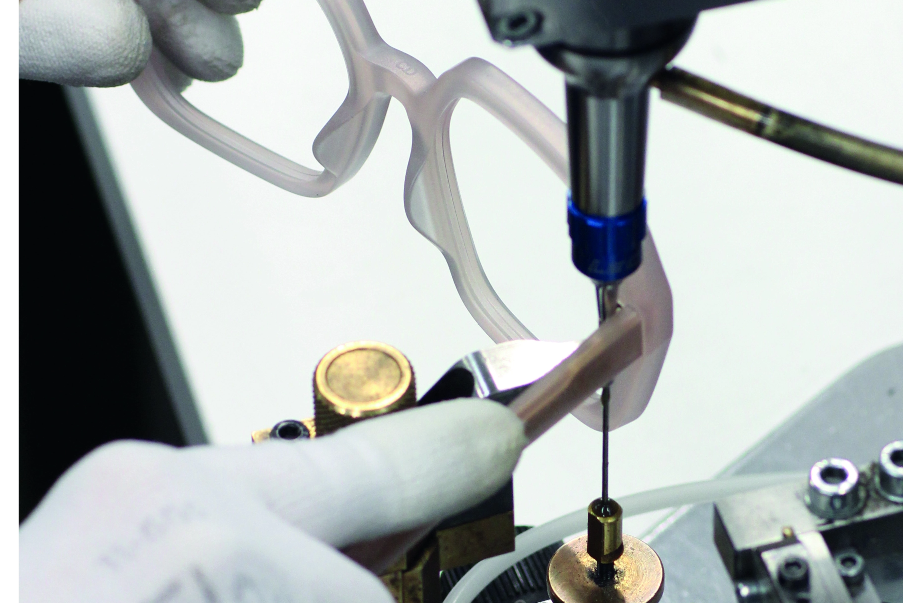

iVision Eyewear is the division actively involved in the phases of design, prototype development, industrialization, and mass production of acetate eyewear using cutting-edge machinery and software. iVision Eyewear is an excellence in the Made in Italy manufacturing sector in the eyewear industry.

Please visit the website www.ivisioneyewear.it for more information.

Divisione R&D

iVision R&D, a specific division dedicated to research and development, focuses on technological innovations to be applied to eyewear. Furthermore, driven by iVision Tech’s commitment to social inclusivity, combined with the shareholders’ extensive experience and passion in the field of digital and electronic technologies, iVision Tech has created an innovative and patented product called “iSee.” This product is specifically designed for the blind and visually impaired individuals.

Production of ophthalmic lenses

iViLENS is a subsidiary of iVision Tech S.p.A. (60% iVision Tech SpA 40% Target), founded in 1993 and headquartered in Plovdiv, Bulgaria. Specialized in the production of ophthalmic lenses, it holds the exclusive rights for marketing LEICA lenses in Bulgaria and North Macedonia, thus adding invaluable value to iVision Tech’s overall eyewear offering.

100 years of history, the luxury Maison Henry Jullien

Henry Jullien is a brand of iVision Tech France (100% owned by iVision Tech S.p.A.), founded in 1921, specializing in the design and production of high-quality eyewear crafted with the ancient and refined technique of Double Or Laminé, which involves the production of frames in laminated gold.

The prestigious craftsmanship of Henry Jullien eyewear is certified by the EPV mark “Entreprise du Patrimoine Vivant” (“Living Heritage Company”).

Find out more about the Maison Henry Jullien:

https://www.maison-henry-jullien.fr/

EYEWEAR FACTORY

MADE IN ITALY

Certifications

iVision Tech represents Italian excellence in the Made in Italy eyewear market. It holds the certifications: ISO9001:2015, ISO14001:2015, and FDA.

Additionally, the company is in the process of obtaining the ISO13485 certification (expected by the second half of 2023).